Components

As a manufacturer of choice for many of today’s automakers – with millions of parts on vehicles all around the world – we engineer our aftermarket components with the highest design integrity and the same quality standards as OE. From pulleys, tensioners and water pumps to actuators, balancers and more, our front engine components improve engine performance and system life.

At Dayco, more than 2,500 design, development and testing hours go into our top performance idler and tensioner pulleys. Each one of our OE quality pulleys is designed using 3D computer-aided design and finite element analysis to guarantee optimal engineering and maximum structural integrity.

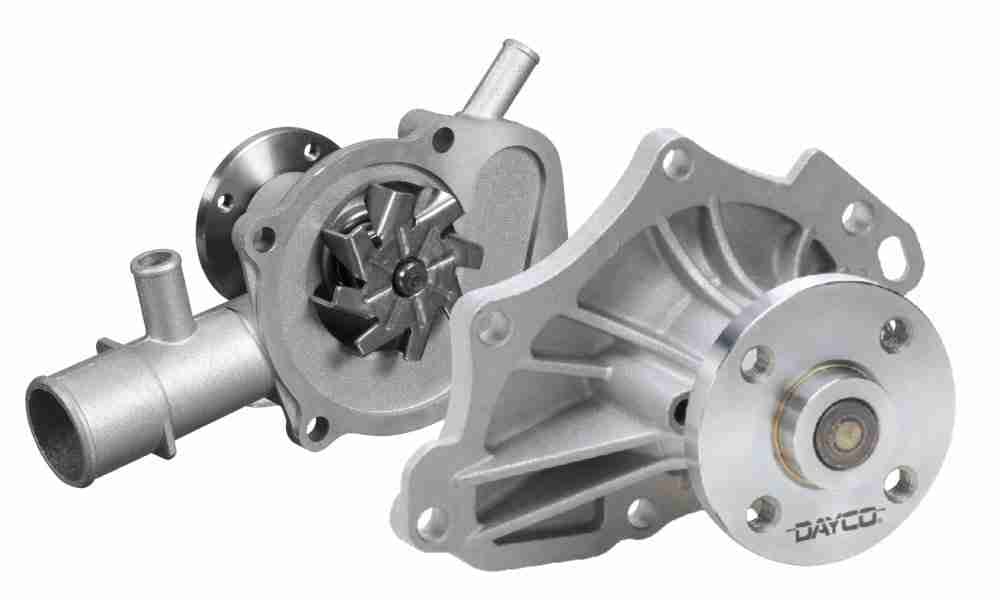

With single source manufacturing, we control every quality aspect of our water pumps’ production from raw material to finished product. Plus, all Dayco water pumps are 100% end of the line leak tested, utilizing a unique failure mode analysis that allows us to identify all opportunities for continuous product improvement.

The choice of today’s OEMs, Dayco’s innovative tensioner design allows for longer product life and overall quieter performance. Unlike tensioners with coil springs, our tensioners feature a flat spring design that prevents fluctuations commonly seen in competitive products.

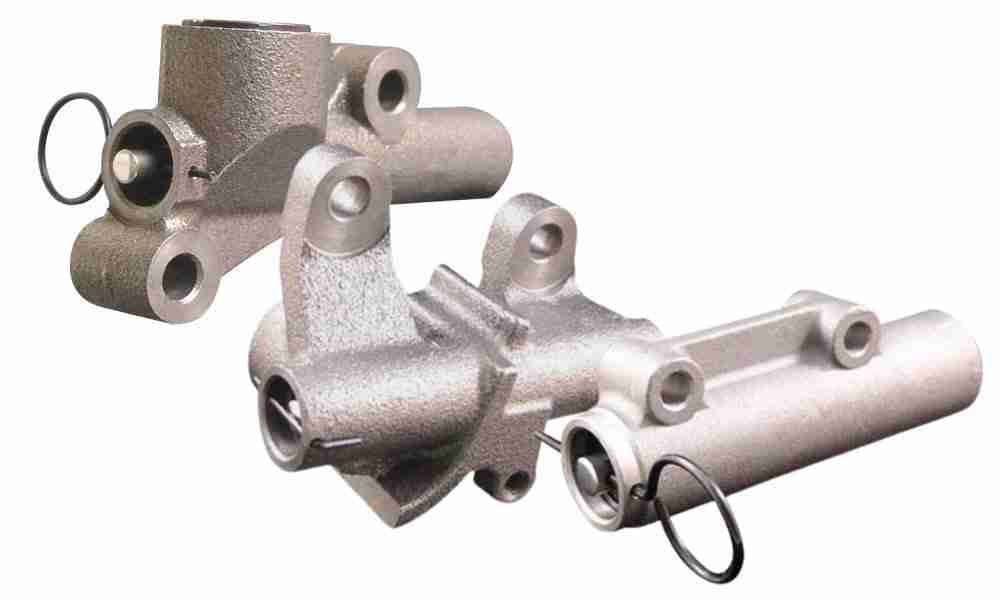

Also known as hydraulic tensioners, Dayco’s hydraulic timing belt actuators are designed to dampen noise, absorb changes in the loss of timing belt tension, and enhance belt life.

Harmonic balancers use special rubber compounds to dampen and remove engine harmonics and add to performance. Our full line of Dayco harmonic balancers address a wide range of vehicle applications – from automotive to heavy-duty to racing, and we use exceptional materials to ensure our balancers exceed OE performance.